Imveliso

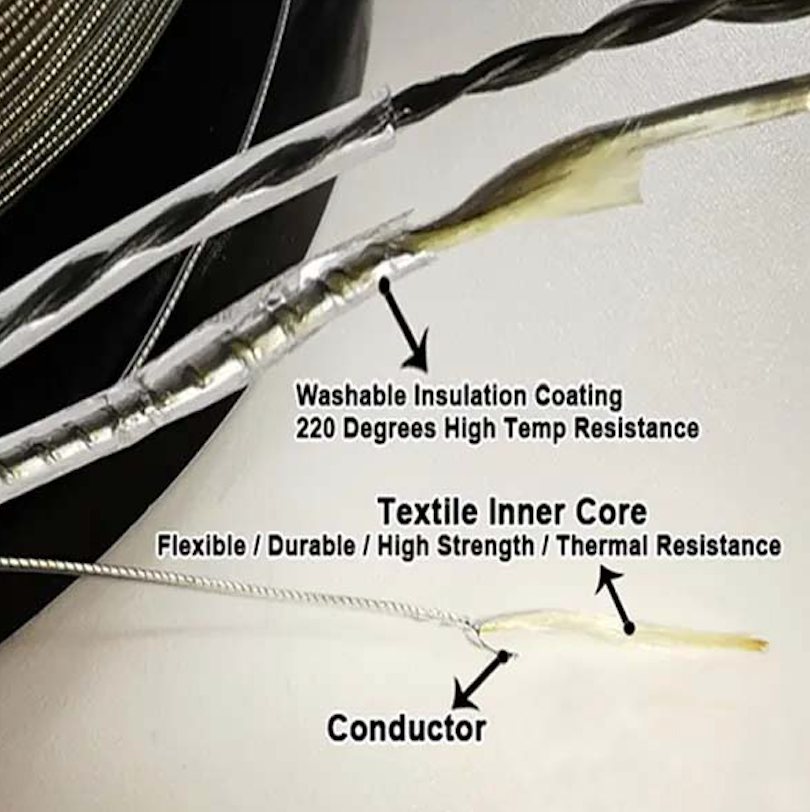

Intsimbi engatyiwayo inyanda ifayibha okanye olulukiweyo ingaphakathi core conductive ucingo lwamalaphu afudumayo

Ingcaciso yeMveliso

I-1-Stainless steel fiber based bundle apho i-diameter yefiber nganye iyi-12µ okanye i-14µ. Umyinge weentsinga uhluka ngokwesiqhelo ukusuka malunga nama-200 ukuya ngaphezulu kwe-1500 imicu. Oku kukunika ixesha elide 'elona lihle eklasini'. Ngenxa yeentsinga ezintle ezisetyenzisiweyo, ezi ntambo zisahlala zibhityile kububanzi obupheleleyo kwaye zibhetyebhetye kakhulu xa zisetyenzwa.

I-2-Sigubungela uluhlu olubanzi lokuchasana olusezantsi olongezelelweyo ucingo olucolekileyo kunye neentambo ezincinci ezineempawu ezihlala ixesha elide neziguquguqukayo, ngokukodwa zethu nge-textile yangaphakathi yeentambo ezincinci zinokwanelisa ukuxhathisa ngemitha nganye oyifunayo kwaye ikunika ukuguquguquka ngakumbi kuyilo kodwa ibonelela ngcono. flex-ubomi kunesiqhelo Cu-iintambo. Kuxhomekeka kwi-alloy elisongelwe yangaphandle enokuthi ifakwe, ikopolo, ialloyi yesilivere njl.

Textile yangaphakathi core iinzuzo micro cables

Ukugoba Ukumelana

Ngenxa yesakhiwo kunye nokudityaniswa kwezinto, ucingo lunokumelana nokugoba okugqwesileyo.

Ukuba bhetyebhetye

Iintambo ezincinci zisebenzisa ifoyile yentsimbi ecekethekileyo njengomqhubi, eqonda ukuguquguquka okukhulu.

Intle kakhulu

Emva kwe-extrusion intambo yethu encinci encinci inokuba yi-0.35mm.

Amandla Okuqina aphezulu

Sisebenzisa i-Aramid / Liquid Crystal Polymer fibers kunye ne-self-engineer fibers high tech fibers.

Ubushushu obuphezulu. Ukuchasa

Sisebenzisa i-aramid okanye intsimbi engenazintsinga yeentsinga zeentsinga zeentsinga, iqondo lobushushu eliphezulu lixhathisa ukusuka kuma-230 ukuya kuma-580 degrees ngokukhetha kwakho.

Ukugqiba kunye nokwaleka

Ehlabathini lakho, kukho imfuneko enkulu yokufakwa kwe-lacquering ye-filaments okanye i-extrusion iyonke yokwaleka phezu kwentambo epheleleyo. Singayenza loo nto, imixholo yethu ye-extrusion ibandakanya i-FEP, PFA, PTFE, TPU njl.

INKCAZELO yejacket ye-INSUlation

| Extrusion | TPE | FEP | MFA |

| Melting Point | 205°C | 255°C | 250°C |

| CUkusebenza okuqhubekayo Ti-emperature | 165°C | 205°C | 225°C |

Iinyanda zeFayibha yentsimbi eStainless

Ulwakhiwo lweMicro Cable yeMicro Cable yeTelaphu yangaphakathi

Ngokusekelwe kwiEmbroided Element yokufudumeza

Intsimbi yentsimbi idibanisa uluhlu olwahlukileyo lokuxhathisa kwireferensi yakho.

| Ububanzi (um) | Iifilaments | Amandla (cN) | Ubunzima (g/m) | Ubude (%) | Ukuqhuba (Ohm/ m) |

| 8 | 1000F x 1 | 69 | 0.420 | 1.10 | 16 |

| 8 | 1000F x 2 | 108 | 0.850 | 1.10 | 8 |

| 12 | 100F x 1 | 24 | 0.110 | 1.10 | 59 |

| 12 | 100F x 2 | 41 | 0.190 | 1.10 | 38 |

| 12 | 100F x 3 | 69 | 0.280 | 1.10 | 22 |

| 12 | 257F x 1 | 59 | 0.260 | 1.10 | 27 |

| 12 | 275F x 2 | 75 | 0.540 | 1.10 | 14 |

| 12 | 275F x 3 | 125 | 0.780 | 1.10 | 9 |

| 12 | 275F x 4 | 130 | 1.050 | 1.10 | 7 |

| 12 | 275F x 5 | 160 | 1.300 | 1.10 | 5 |

| 12 | 275F x 6 | 180 | 1.500 | 1.10 | 4 |

| 12 | 1000F x 1 | 100 | 0.950 | 1.10 | 7 |

| 12 | 1000F x 2 | 340 | 1.900 | 1.10 | 4 |

| 14 | 90F x 2 | 46 | 0.190 | 1.10 | 44 |

| 14 | 90F x 1 | 25 | 0.110 | 1.10 |

Textile yangaphakathi core conductive ngocingo ezahlukeneyo ukuxhathisa

| I-Conductor yangaphandle | Textile Inner Core | Ububanzi mm | Ukuqhuba ≤Ω/m |

| Ubhedu 0.08mm | 250D Poyester | 0.20±0.02 | 6.50 |

| Ubhedu 0.10mm | 250D iPolyester | 0.23±0.02 | 3.90 |

| Ubhedu 0.05mm | 50D Kuraray | 0.10±0.02 | 12.30 |

| Ubhedu 0.1mm | 200D Dinima | 0.22±0.02 | 4.00 |

| Ubhedu 0.1mm | 250D iPolyester | 1*2/0.28 | 2.00 |

| Ubhedu 0.1mm | 200D Kevlar | 0.22±0.02 | 4.00 |

| Ubhedu 0.05mm | 50D iPolyester | 1*2/0.13 | 8.50 |

| Ubhedu 0.05mm | 70D iPolyester | 0.11±0.02 | 12.50 |

| Ubhedu 0.55mm | 70D iPolyester | 0.12±0.02 | 12.30 |

| Ubhedu 0.10mm | Umqhaphu 42S/2 | 0.27±0.03 | 4.20 |

| Ubhedu 0.09mm | I-polyester ye-150D | 0.19±0.02 | 5.50 |

| Ubhedu 0.06mm | I-polyester ye-150D | 0.19±0.02 | 12.50 |

| Ubhedu lweTin 0.085mm | 100D Kuraray | 0.17±0.02 | 5.00 |

| Ubhedu lweTin 0.08mm | 130D Kevlar | 0.17±0.02 | 6.60 |

| Ubhedu lweTin 0.06mm | 130D Kevlar | 0.16±0.02 | 12.50 |

| I-Tin Copper 0.10mm | 250D iPolyester | 0.23±0.02 | 4.00 |

| Ubhedu lweTin 0.06mm | I-polyester ye-150D | 0.16±0.02 | 11.6 |

| Ubhedu lweTin 0.085mm | 200D Kevlar | 0.19±0.02 | 5.00 |

| Ubhedu lweTin 0.085mm | I-polyester ye-150D | 0.19±0.02 | 6.00 |

| ISilver Copper 0.10mm | 250D iPolyester | 0.23±0.02 | 3.90 |